|

||||||||

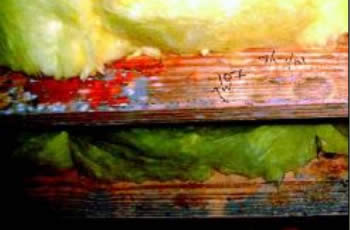

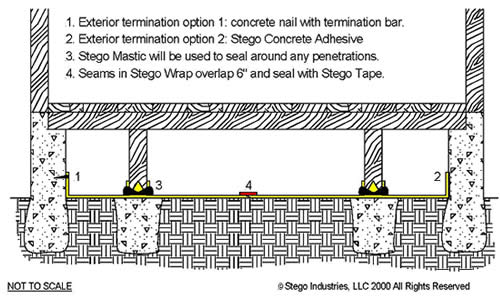

For these reasons and others including cost of construction, many experts have been discussing alternative options for vented crawlspaces. The most common choice is to close the crawl space. In practice this means treating the crawl space as a sort of miniature basement. The US Department of Energy states, If you have or will have an unventilated crawl space, then your best approach is to seal and insulate the foundation walls rather than the subfloor. The advantages of insulating the crawl space are as follows: 1. You can avoid the problems associated with ventilating a crawl space. 2. Less insulation is required (around 400 square feet for a 1,000-square-foot crawl space with 3-foot walls.) 3. Piping and ductwork are within the conditioned volume of the house so they don't require insulation for energy efficiency or protection against freezing. 4. Air sealing between the house and the crawl space is less critical. The US Department of Energy and the authors of "To Vent Or Not To Vent" agree that a key to sucessfully designing an unvented crawl space involves sealing the floor from moisture. Depending on your water table this may involve several solutions. In the case of a high water table it might be best to consider the use of waterproofing and a thin slab of concrete. Generally this is not necessary and the use of a plastic barrier will suffice. Many older articles simply recommend the use of 6 mil poly, however as Crosbie and Zoeller write, "The typical 6 mil polyethylene easily can be ripped by crawling on it, and the edges and seams are difficult to seal to the walls." For this reason a better choice would be the use of a polyolefin plastic barrier with an extremely low permeance. Most experts agree that the permeance level should be as close to 0.01 perms as possible. A low as possible thus keeping the humidity low and reducing the chances for mold and mildew.

As always, if you would like to ask more questions about this or other technical topics give us a call at 877-711-4822 - 8-5 PST. Live people for technical and sales support - an Internet first! Disclaimer: Advice and information given through our representatives is checked for usability and conformance with most codes. You as the user, however, have the responsibility for verifying conformance with local codes and standards and ensuring a safe installation. Although HVACQuick.com may employ and use professionals, their advice is not meant as substitute for professional engineering services. It is the customer's responsibility to hire and retain suitable engineering and architectural professionals as required. |

HVACQuick.com

high performance ventilation & green products - large in-stock inventory!

- team@hvacquick.com

- 888-855-7229